A coded welder is someone who has passed a Welder Approval Test in a specific welding process. Coded welders are required for structural steel, pressure vessels and high pressure pipework in heavily regulated industries where compliance is critical. Many industries require coded welding to UK and international standards to ensure compliance and safety.

TL;DR – Coded welding (UK)

- A coded welder has passed a Welder Approval Test to a specific code (e.g., BS EN ISO 9606, ASME IX).

- Codings are process-, position- and material-specific; one approval doesn’t cover another.

- Tests follow a WPS and may include visual checks, bend tests, macro-etch and NDT (MT/PT/UT/RT).

- Retesting is required periodically (commonly every 2 years) to maintain compliance.

- Typical applications: structural steel, pressure vessels and high-pressure pipework in regulated sectors.

- We provide multi-coded welders and mobile support across the UK for safety-critical projects.

How welder coding works

To become a coded welder you must meet the regulatory requirements and industry standards which are outlined in the welding codes. Code qualification is achieved by passing the welder approval codes and practical tests to prove you can meet those standards. Formal training such as apprenticeships or college courses is a common way to develop the required welding skills.

Working to a specific welding spec, a welding sample is submitted for testing. Testing proves the welder can meet the mechanical and quality requirements for safety critical applications. Coded welders must interpret complex Welding Procedure Specifications (WPS) and welding drawings, and where relevant the Procedure Qualification Record (PQR).

These are the welding tests required to meet code requirements and standard welding codes, to prove welders are competent and compliant to industry standards.

Being coded in one spec does not mean you are coded in another. Each spec has its own requirements and most highly regulated industries demand compliance to strict standards.

Testing is not a one off, welders must be retested periodically to maintain their certification. Practical experience and theoretical knowledge are both important and welder passes are only awarded to those who have passed practical tests demonstrating the skills required. Coded welders are retested every 2 years to ensure ongoing compliance to welding standards.

How do you become a coded welder?

In the UK welder certification is based on the British Standards Institute’s ISO standards and the International Standards Organisation. The American Society of Mechanical Engineers has its own standards and the American Welding Society is used for structural welding in the US. Certified welders must pass welding approval tests and have practical experience. The ISO standard applies globally and provides guidelines for quality and safety across all industries.

Each code is for a specific job, some are more general and some are more specific. More specific codes require parameters to be assigned by a welding inspector. Welding codes and procedures are key to meeting quality requirements in welding jobs.

How do you become a coded welder?

A welding specification demands that welds are tested to that specification. The welder may produce a sample that mirrors the position closely. You are expected to produce a weld following written instructions. An approved CSWIP examiner will then perform a welding examination on your weld, encompassing the following:

- Visual or Surface Inspection

- Destructive Bend Test

- Nick Break Fracture Test

- Macro Etch

Non destructive testing and bend tests are used to assess the quality of the welded joint and ensure it meets the required standards. Depending on scope, NDT may also include MT, PT, UT or RT, and testing demonstrates the welded joint meets mechanical and quality requirements under the specified environmental conditions.

If the inspector passes each of the above, the welder is then coded to that specification. Welder coding systems and welder coding are used to verify a welder’s skill in specific welding methods and welding processes, tied to a particular specification and specific welding configuration.

Multi coded welder

Being coded in one spec DOES NOT mean you’re qualified in another. Many welders have practical experience but only those who pass the welding approval test and meet the quality requirements become certified welders. Our coded welders cover all of the above and more and are generally tested every couple of years. Many welders keep multiple approvals current so they can work across arc welding processes in highly regulated sectors.

Common welding codes

Welding codes are the standards of practice to ensure quality is maintained throughout the process. Common welding codes such as ASME IX and BS EN ISO are the standard welding codes that set the code requirements for quality, safety and compliance in welding.

These codes are mandatory for legal, safety and industry standards especially for pressure vessels, piping and structural welding. Welding codes are developed by various associations to ensure quality throughout the welding process.

In the UK you will operate under one of the following codes:

- BS – National British Standard

- ISO – International Standards Organisation

- BS EN – European British Standard European Standard

- AWS – US American Welding Society

- ASME – American Society of Mechanical Engineers

The most common codes are:

- BS EN ISO 9606

- BS 4872

- BS EN ISO 15614 -1

- AWS D1.1 / D1.2 / D1.6

- ASME Section IX

These welding codes and their code requirements ensure welders are qualified and welding procedures meet safety and quality standards.

Types of welding

There are many types of welding and welding methods, each for specific applications. Choosing the right welding process is key to achieving the required weld quality and meeting industry codes and standards.

TIG welding

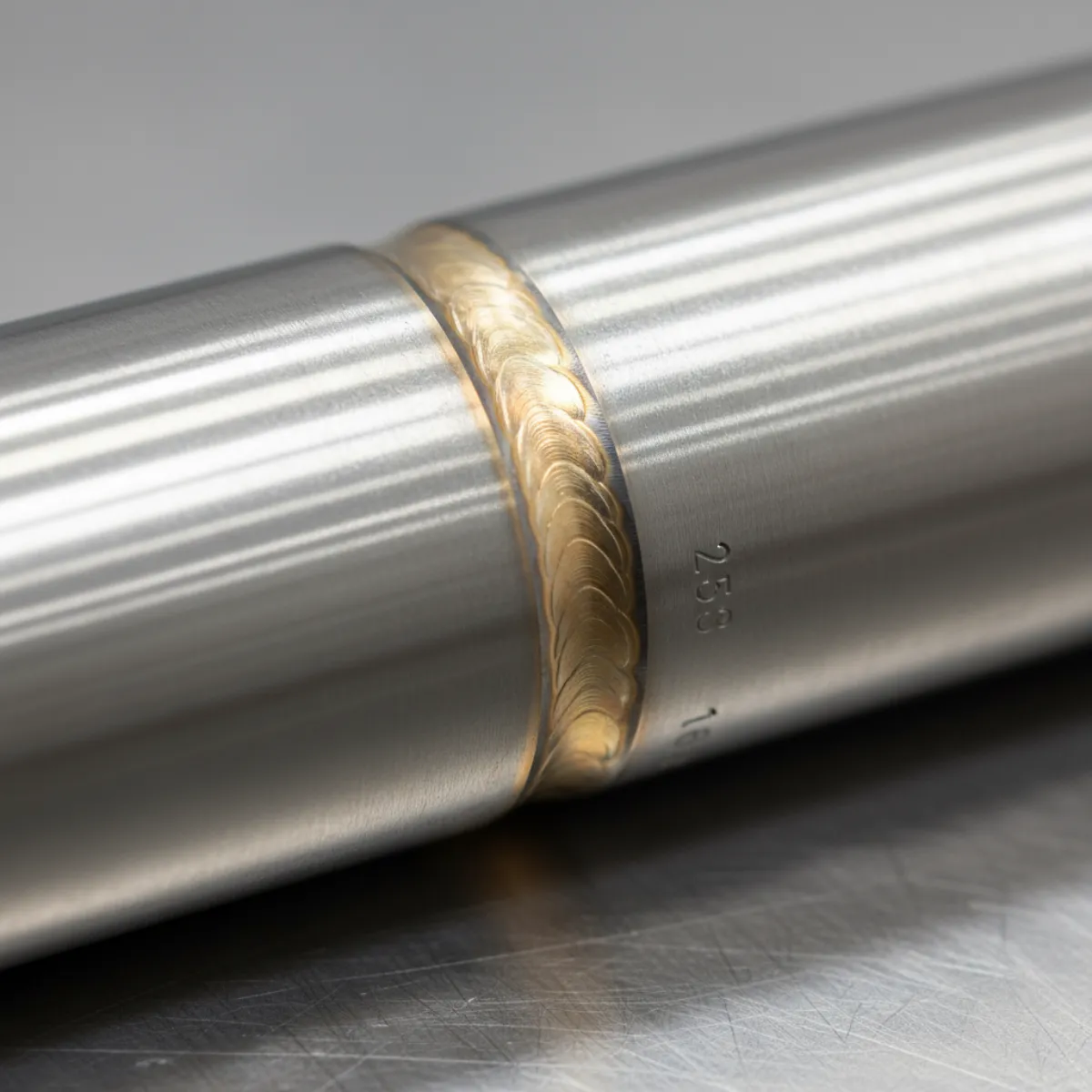

Kee Engineering use TIG welding, also known as gas tungsten arc welding, for high quality welds. TIG is one of the specific welding methods used when weld integrity is critical. TIG produces no splatter and minimises defects during the welding process, and is widely used across arc welding applications.

MIG welding

MIG is one of the most common industrial welding techniques, produces high quality welds much faster than other methods. MIG can weld many different metals and alloys and is a mainstay in arc welding for structural steel and pressure vessel welding where appropriate procedures exist.

MMA welding

AKA the Stick welding method, also called Shielded Metal Arc Welding, is a low cost method that can be used in any environment and position and is very versatile. Stick welding remains vital for welders working on site and in challenging conditions.

Fusion welding

We use fusion welding to weld polyethylene pipes such as MDPE. They use heat and copper wires to melt the ends together. Gas and water piping usually requires fusion welding. Fusion welding can also be used for acidic environments.

Our coded welders and services

Our multi coded welders offer coded welding for load bearing structures, off shore structures and projects that require structural integrity. With experience of working to many different specifications, materials, diameters and thicknesses our certified welders will ensure the highest standards for safety critical applications. We cover the whole of the UK.

There is a high demand for skilled welders and certified welders across industries like aerospace, oil and gas, construction, energy and manufacturing so job security is improving.

We operate out of a purpose built industrial unit but can also provide a mobile service to support you wherever you are based. We provide coded welding services for structural steel, pressure vessel welding and pressure pipework – aligned to BS EN ISO and ASME IX as required by the project.

Click –> Coded welding to find out more about our services.

Faqs

It means the welder has passed a witnessed Welder Approval Test to a defined standard and scope - process, position, material and thickness.

Primarily BS EN ISO (e.g., 9606 for welder qualification and 15614-1 for procedures). Internationally, ASME Section IX and AWS structural codes are also used where specified.

Approvals require continuity and periodic retesting - commonly every 2 years - to remain valid and compliant.

TIG/GTAW, MIG/MAG, MMA/Stick and fusion welding for thermoplastic pipe (e.g., MDPE), all delivered to an agreed WPS and PQR.

Yes - we provide nationwide mobile coded welding for structural steel, pressure vessels and high-pressure pipework.